Salt Spray Test Chamber

The salt spray test chamber can simulate the natural salt spray environment to test the corrosion resistance of samples or metals. It is widely used in corrosion resistance tests of electronic components, mechanical parts, metal materials, etc.

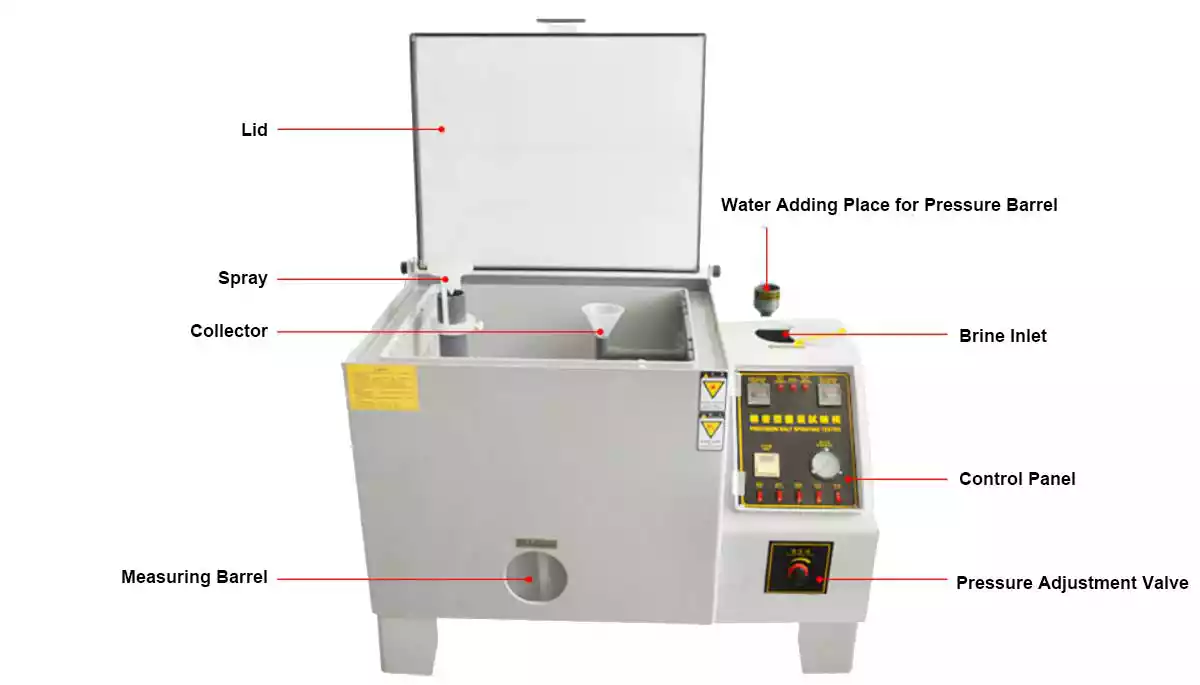

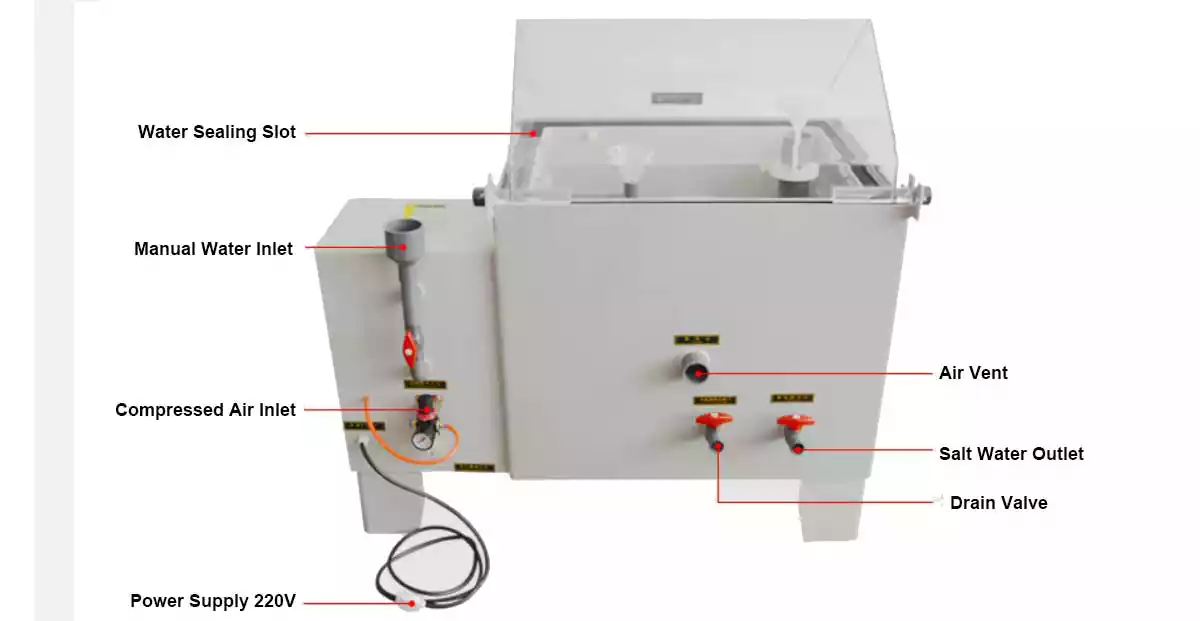

Product Details of the Salt Spray Test Chamber:

Main Technical Data of our Salt Spray Test Chamber:

| Model | LGD -60 | LGD -90 | LGD -120 | LGD -160 | LGD -200 |

|---|

| Inner Size | Width (mm) | 600 | 900 | 1200 | 1600 | 2000 |

|---|

| Depth (mm) | 450 | 600 | 1000 | 1000 | 1000 |

|---|

| Height (mm) | 400 | 500 | 500 | 500 | 500 |

|---|

| Testing Method: | +10 - 55 ℃ |

|---|

| Humidity Range: | >= 85 % R.H |

|---|

| Temperature Uniformity: | ± 2 ℃ |

|---|

| Temperature Fluctuation: | &± 0.5 ℃ |

|---|

| Fog Deposition: | 1-2ml / 80 Cm2 (Tested at least 16 hours and take the average value) |

|---|

| Spray Method: | Continuously / Periodically |

|---|

| Temperature Range: | NSS, ASS, SS, CASS |

|---|

| Power Supply: | 220V |

|---|

| Testing Chamber Temperature: | (NSS ACSS) 35℃ ± 1℃/CASS 50℃ ± 1℃ |

|---|

| Pressure Barrel Temperature: | (NSS ACSS) 47℃ ± 1℃/CASS 63℃ ± 1℃ |

|---|

| Salt Water Temperature: | 35℃±1℃ |

|---|

| Salt Water Concentration: | Sodium chloride concentration 5% or add 0.26g copper chloride per liter to 5% sodium chloride solution |

|---|

| Sample Rack: | Can tilt 15-30 degrees.(2 layers) |

|---|

Product Features of the Salt Spray Test Chamber:

1. PVC material is integrated externally and internally; the PVC boards are thickened, with excellent corrosion resistance. The highest temperature can be 85℃.

2. Intelligence system, the indication light will be on if any error occurs.

3. Hiden water level observation window with transparent acrylic lid design, good thermal insulation performance. We can observe the inner samples directly.

4. Precision glass spray nozzle makes the spray fog diffuse evenly. The machine can work continuously for 4000 hours without a crystalline salt block.

5. Double over temperature protection. It will alarm if the water level is too low.

6. Adopts manual/automatic water-adding system to adapt to different experiment environments. If the user chooses automatic mode, connect to tap water.

7. Digital temperature controller, PID control, the error is only ±0.3℃.

8. The working chamber adopts direct steam heating. Rapid and uniform temperature rise, such can reduce standby time.

9. The spray is equipped with a conical disperser, a fog guide, and adjustment.

10. The salt spray test chamber also has the function of defogging. Such a function can be used to stop the experiment or makes the machine shown down temporarily and make the inner salty air out by force.

11. Adopt high precision multifunctional timer.

12. Good sealing performance. It can prevent the inner salt fog thoroughly.

Other Details of the Salt Spray Test Chamber:

1. Thickened PVC board, which can bear a temperature of 85℃.

2. Transparent acrylic lid. It will not deform even at high temperatures.

3. The sample rack is made of ABS, with a load capacity of 15 kg. Also, we can adjust the angle to make the salt fog can be dispersed evenly. The size and shape can also be customized if needed.

4. Glass fog spray, we can adjust the spray amount and angle easily.

Product Applicable Standards:

RELATEU STANDARDS CNS 3627,3885,4159,7669,8866;JIS D-0201,H-8502,H-8610,K-5400,Z-2371,ISO3768,3769,3770;ASTM B-117,ASTM B-268 B-268 GB-T2423 GJB150

Real Tested Sample Pictures:

We can test the following samples:

PS: The air compressor is not included, so the user will have to purchase it himself.

What is a salt spray test?

There are two ways: a natural environmental exposure test and an artificial accelerated simulated salt spray environment test. The salt spray test is an environmental test to evaluate the corrosion resistance of products or metal materials by manually simulating the salt spray ecological conditions in salt spray testing chambers.

Artificial simulated salt spray environment test adopts test equipment with a particular volume space. We usually use a salt spray testing machine to create a salt spray environment by the artificial method in its volume space to evaluate the salt spray corrosion resistance and quality of products. Compared with the natural environment, the salt concentration of chloride in the salt spray environment can be several or dozens of times the salt spray content in the natural environment, significantly improving the corrosion speed. The time for salt spray tests on products is also considerably shortened. Suppose a product sample is tested in a natural exposure environment. In that case, its corrosion may take one year, while we can get similar results in 24 hours under an artificial salt spray environment.

How to use Salt Spray Test Chamber?